Search

Electrification and smart hydraulics anchor our strategy

BV Ramesh, Managing Director, and Sheshadri Raman, Chief Business officer, Mobile Applications, Bosch Rexroth (India)

Revolutionising Fleet Management

In the demanding world of heavy equipment operation, maintenance often takes a backseat, leading to costly breakdowns and inefficiencies. As construction and mining fleets work around the clock in remote locations, overlooking essential maintenance tasks can severely impact productivity.

Liebherr at IFAT 2024 in Munich

Liebherr presents two wheel loaders: L 507 E and L 556 XPower®

Building the Future

The market for wheel loaders is seeing fresh traction due to the buoyancy in road construction activities. Fresh off take of coal due to a surge in thermal power production is adding to the demand.

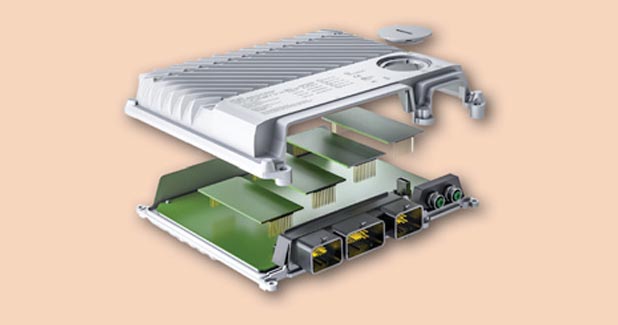

Data exchange with B&R Automation PC Mobile 3100

It can collect large amounts of data from multiple equipment.

Data exchange with B&R Automation PC Mobile 3100

Nowadays, self-driving machines are playing a major role in boosting agricultural productivity.

Revolutionising construction

Automation in construction equipment has the potential to improve productivity, safety, and efficiency, leading to significant advancements in construction practices.

Industry 4.0 is helping machine builders to implement digitalisation

Himanshu Sharma, Head – Marketing and Corporate Communication, B&R Automation, speaks on the evolving digital technologies in the construction equipment industry.

Entering an era of transformation

Off-the-road tyre manufacturers and suppliers are facing brand-new difficulties as a result of technological advancements and evolving end-user needs that are pushing the market into uncharted terrain.

Electric Construction Machinery on the Rise

Electric machinery often requires less maintenance and has a longer lifespan compared to its diesel counterparts, making them a more cost-effective solution in the long run.

Predictive Maintenance: A New Paradigm in Heavy Equipment

Predictive maintenance can help fleets avoid breakdowns while reducing maintenance costs by predicting when parts will fail based on performance data and other information.

Predictive maintenance: A new paradigm in heavy equipment

Predictive maintenance can help fleets avoid breakdowns while reducing maintenance costs by predicting when parts will fail based on performance data and other information.

Predictive maintenance: A new paradigm in heavy equipment

Predictive maintenance can help fleets avoid breakdowns while reducing maintenance costs by predicting when parts will fail based on performance data and other information

B&R introduces high-end PC for mobile machinery

Tractors and implements can optimise harvesting efficiency, for example, by exchanging information such as speed and load capacity.

Digital continuity in vehicle using open standards

The automobile industry inclusive of the off highway and mobile machinery are cost sensitive at the same time technology craving industries. To keep pace with technological advancements these industries constantly invest heavily in research and development projects.

OPC UA over TSN – Unified standard for the IIoT

In order to keep pace with technological advancements off-highway and mobile industry constantly invest heavily in research and development projects.

New CTO for the WOLFF Pack

The 54-year-old holds a university degree in Electrical Engineering and has spent a significant part of his professional life in the crane industry.

Paving the Road to Success

To be competitive in a global market, it is essential for OEMs explore and take the first step towards adopting advanced automation and digitisation solutions. Saurabh Kulkarni, Mobile Automation Expert at B&R Industrial Automation, Austria writes.

We are a preferred automation partner for market leaders

B&R India has established seven offices in major cities of India and has expanded its Pune office space to match the growth.

Safety for mobile Machines

As mobile machinery becomes increasingly automated, its manufacturers must address the requirements of the European Machinery Directive and the topic of safety technology.

The level of automation in CE has skyrocketed

B&R's modular X90 control and I/O system brings all the functionality of advanced automation solution to construction equipment.

Hydraulic Cylinders

Cylinders allow hydraulic systems to apply linear motion and force without mechanical gears or levers by transferring the pressure from fluid through a piston to the point of operation. Hydraulic cylinders are used for creating mechanical force in a linear motion.

Digital technology for mobile equipment is in transition

B&R Industrial Automation offers high-performance and technologically advanced products and solutions to construction and off-highway equipment OEMs.

Predictive Maintenance: A Paradigm Shift

Timely and quick maintenance is a key factor in off-highway equipment. Trucks and equipment used in the construction and mining industry are expected to operate 24/7 at remote locations.

Machine Control -The way you want it

Murphy by Enovation Controls works with OEMs globally bringing together different aspects of their equipment enhancing features, making it user-friendly, smarter, safer, and ultimately more efficient.

Complete motor control

Webtec's new CV120 hydraulic combination valve offers complete motor control for mobile machinery

Kohler guarantees Stage V certification for entire diesel range

Kohler has reached its latest milestone of Stage V certification for KDI engines in the 19-56 kW power range. Thanks to the exciting partnership with one of the agencies accredited to the European Union for the certification of internal combustion engines, the first half of 2018 was devoted to undertaking thorough tests and analysis on the Kohler range of diesel engines with the aim of verifying their compliance with all the requisites indicated by the legislator.

Bonfiglioli opens new facility in Chennai

Bonfiglioli Transmissions, the Indian subsidiary of Bonfiglioli Riduttori S.p.A, opened its new manufacturing facility in Chennai.

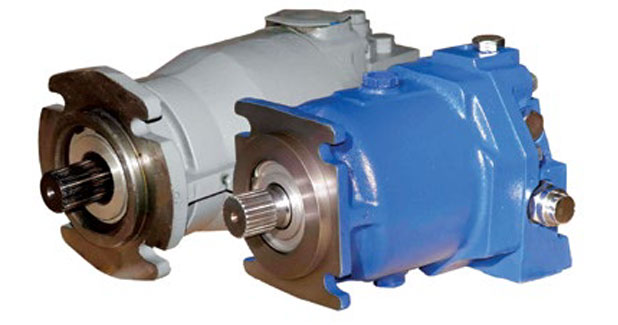

Hydraulic Motors

In order to match the requirements of equipment market, hydraulic motor manufacturers are coming out with new improved designs that enable better efficiency and productivity with the machines.

Astec to exhibit at Intermat 2018

Astec, Inc., an Astec Industries company, will exhibit at the Intermat 2018 international exhibition for construction and infrastructure, to be held during April 23-28 in Paris, France.

DEUTZ engine becomes EU Stage-V compliant

DEUTZ said it has received a certificate for the EU Stage-V emission directive for mobile machinery, making it the first engine manufacturer globally to receive the certificate, which will apply from 2019. On September 6, the German Federal Motor Transport Authority formally certified the DEUTZ TTCD 6.1 engine for Stage V, the company said in a press release.

German CE sector grows

Turnover achieved by German manufacturers of construction equipment in 2014 grew by eight per cent, equaling ?8.4 billion in total, and, with this, is higher than was originally expected. This amount is about the same as was reached in 2006.

Our innovative systems contribute to reduced emissions

We are positive that with the new government at the Centre, the pace of economic activity will grow at a much faster rate in the near future and our opportunities would be linked to the same, says Upinder Razdan, Managing Director, Danfoss Power Solutions

Hybrid Stone Crusher

In mobile machines used in construction industry, the investment in hybrid technology can be justified just with reduced fuel costs, rather than in abstract green values known from the automotive industry.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com